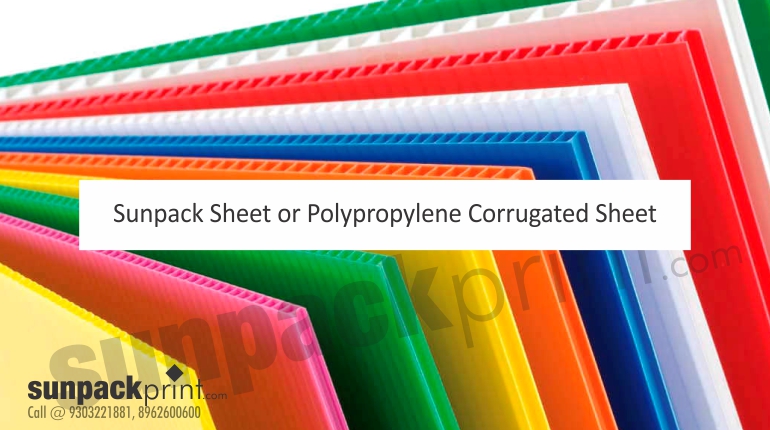

Sunpack Sheet or Polypropylene Corrugated Sheet is two names of the same product. A sunpack sheet or a pp corrugated sheet is manufactured by fabrication process. This fabrication is done of quality crude materials, preferably from industrial waste or industrial by products in Polypropylene, Poly vinyl chloride or plastic industries. These crude materials are melt and compressed together in a specially designed compressing machine which has controlled pressure system. This compression leads to formation of thin sheets of Polypropylene those are adhered together. A special corrugated layer of polypropylene sheet is put in between thicker layers of plain compressed sheets. This corrugated sheet adds strength and volume to the compressed sheet and helps making the sheet straight tear free, and light weight.

A surface layer is put on both the surfaces of a sunpack sheet surfaces. This layer is popularly known as skin. This skin makes the surface of the sheet smooth and ready to be printed upon. There are provisions of laminating the surfaces of the sheets after printing to make the sheets appear glossy and shining.

These sunpack sheets or polypropylene sheets are lightweight, easy to carry and install, tough, strong, almost unbreakable, tear resistant, water resistant, and weather resistant material, ideal for outdoor advertising and marketing. Since the raw material of sunpack sheets are inexpensive, sunpack sheets also are economical and cost effective.

Sunpack sheets or Polypropylene sheets are available in different colors and can be printed upon in multicolor printing. These sheets and the printing on them are clearly visible even from a distance making sunpack sheets the latest concept and most desired advertising medium.